Sommaire: Les ballonnements, parlons-en ! On ne va pas se mentir, c’est un sujet pas très glamour, mais qui peut sérieusement nous gâcher la vie. Cette sensation de gonflement dans le ventre, c’est juste pasLire la suite…

Repas entre amis : nos idées de recette pour un moment conviviale

Sommaire: Organiser un repas entre amis est toujours un moment convivial et agréable. Mais pour les rendre réussis, il est important de bien s’organiser. Si vous êtes à court d’idées, pas de panique ! DansLire la suite…

Comment bien apprendre le code de la route ?

Sommaire: Pour beaucoup, apprendre le code de la route peut être une expérience stressante et frustrante. Cependant, il existe certaines techniques qui peuvent vous aider à mieux apprendre et à réussir votre examen du codeLire la suite…

Excellence linguistique : Pourquoi partir en Amérique ?

Sommaire: Les meilleures destinations pour un voyage linguistique en Amérique ! Que vous soyez un débutant en langue ou un locuteur avancé, un voyage linguistique est l’occasion idéale pour améliorer vos compétences linguistiques tout enLire la suite…

Trancheuse à jambon : en quoi est-ce efficace ?

La trancheuse à jambon est une petite machine destinée à couper de la viande et autres aliments avec des avantages assez intéressants. Nous allons vous parler des différents avantages de la trancheuse à jambon. VousLire la suite…

Distributeur croquettes chat : optez pour un jouet amusant

Votre chat a tendance à se goinfrer, à manger l’intégralité de sa gamelle en seulement quelques secondes ? Dans ce cas, il est nécessaire de trouver des solutions, qui vous permettront de faire durer saLire la suite…

Comment gagner le quinté

Sommaire: Le casino en ligne et les paris sportifs traditionnels ne sont pas les seuls à attirer le regard des joueurs. Ils peuvent également se frotter au Turf qui connaît un succès phénoménal depuis deLire la suite…

Ceinture homme : est-ce nécessaire ?

En matière d’accessoires, les femmes sont plus gâtées que les hommes, mais ces derniers ne manquent pas non plus d’accessoires spécialement conçus pour eux, comme c’est le cas de la ceinture bretelles. Il est évidentLire la suite…

Comment dessiner des dessin d’halloween

Apprendre comment dessiner des dessin d’halloween Vous aimez beaucoup la fête d’halloween qui nous vient des États-Unis mais parfois vous êtes à cours d’idée pour apprendre aux enfants comment dessiner des dessin d halloween. EnLire la suite…

Croquette chat : en quoi est-ce bénéfique ?

Les croquettes permettent aux chats de se revigorer et être en très bonne forme durant toute la journée. Il s’agit d’une nourriture idéale et bénéfique pour de nombreuses raisons. Nous allons vous citer quelques avantagesLire la suite…

Tutoriels minceur et santé : comment maigrir sans nuire à sa bonne santé ?

Perdre du poids ne doit pas seulement se faire pour des raisons de beauté, vous devez aussi garder en tête votre santé. En effet, ce n’est pas les régimes qui vous permettent d’atteindre une perteLire la suite…

Impression : quels sont les meilleurs moyens ?

L’impression a pris une grande partie dans la réalisation de nos travaux et nos projets, nos études et même pour préparer une campagne publicitaire. On peut procéder à l’impression à travers plusieurs solutions. On peutLire la suite…

Blog santé : que peut-on apprendre grâce à un blog santé ?

Le blog santé regroupe un tas d’informations relatives à l’univers de la médecine. Via notre article du jour, nous allons vous parler des complémentaires mutuelles santé plus précisément comment en choisir une parmi toutes lesLire la suite…

Jupe longue : avec quoi peut-on la porter ?

Dans le domaine de la mode, et plus spécialement la mode féminine, on retrouve beaucoup de pièces qui se ressemblent en apparence, mais qui sont pour les professionnels, toutes différentes, à cause de quelques détails,Lire la suite…

Valise diagnostic : Quels les sont les meilleurs modèles recommandés ?

A l’ère du progrès et du tout électronique , les pannes mécaniques sont vraiment difficiles à détecter . Si l’automobiliste est pressé , ça devient de l’impossible simplement . De nos jours , il fautLire la suite…

Sur-matelas : comment le choisir ?

Vous ne retrouvez plus le confort quand vous dormez sur votre matelas ? Vous avez des troubles de sommeil à cause de votre matelas qui ne s’adapte pas à votre morphologie ? Alors la solutionLire la suite…

Blog lifestyle : quelles activités conseillées pour mincir ?

Nombreuses sont les personnes qui désirent perdre du poids, mais peu savent réellement comment faire. Ce que vous devez savoir c’est qu’il n’y a pas réellement de solution magique ou miraculeuse qui sort du communLire la suite…

Quelle est l’utilité du panneau immobilier en akylux ?

Quand vous êtes une agence immobilière, vous n’avez pas d’autre choix que de commander des panneaux sur https://www.topakylux.com/impression-panneau-immobilier-akilux-p90.html. Ce type de panneau est à la fois résistant et de qualité. Il est fabriqué à partirLire la suite…

Rentiles : Une voiture de rêve ?

La location voiture Réunion est un excellent phénomène dont il faut se féliciter. En effet il est tout à fait possible pour chacun d’avoir le résultat qu’il mérite. En effet il est très intéressant pourLire la suite…

Blog high-tech : comment s’assurer que les informations diffisées sont fiables ?

Il existe aujourd’hui, des milliers d’interfaces en ligne, qui diffusent plusieurs informations à la fois, surtout lorsqu’il s’agit d’un domaine ou les nouveautés ne cessent d’accroitre, comme par exemple le domaine du high-tech. Plusieurs personnesLire la suite…

Agence de communication : à quoi ça sert ?

Vous êtes un auto-entrepreneur qui a besoin d’agrandir son entreprise et de l’améliorer en matière de visibilité et de connaissance dans le marché ? pas de panique nous avons juste ce qu’il vous faut. NousLire la suite…

Woopets : Un chien pour les enfants ?

Le beagle est un chien qui est d’un grand respect. C’est pourquoi il est assez facile d’avoir un chien de type beagle qu’il est logique pour de nombreuses familles d’opter pour une nouvelle tendance animale.Lire la suite…

Appart hôtel : quelle est la durée de votre séjour ?

Pour loger dans de bonnes conditions quand vous êtes loin de chez vous, mieux vaut louer un appart hôtel. Comme vous le lirez sur apparthotelparis.info, il s’agit en fait d’un appartement meublé où vous profitezLire la suite…

Underground : à quoi ça consiste?

Sommaire: La culture underground est une approche constituée de plusieurs personnes ayant en commun des principes, des passions et des philosophies sur les divers domaines de la vie. Comme n’importe quelle autre doctrine ou approche,Lire la suite…

Comment faire une niche a chien ?

Apprendre comment faire une niche On peut faire une niche soi même faut-il encore être un peu bricoleur! En effet, vous pouvez fabriquer une niche à chien avec des vieilles palettes, mais avant tout ilLire la suite…

Machine à café : comment la choisir ?

Le café est l’indispensable du matin, pour bien commencer la journée et être en forme, si vous êtes un addict de la caféine, il vous faut une bonne machine à café, c’est un must dansLire la suite…

Dératisation : quel sont ses tarifs ?

Votre immeuble est envahi de rat et votre logement n’a pas échappé à cette infestation de rongeurs, c’est pour cela que vous êtes à la recherche d‘un moyen efficace d’éliminer ces rongeurs ?Mais alors pourquoiLire la suite…

Boîtier additionnel moteur essence : quels sont ses avantages ?

Vous avez un véhicule avec moteur essence ? Vous souhaitez plus de puissance et de performance pour votre moteur ? On vous suggère l’installation d’un boitier additionnel pour essence. Il vous assure plus d’efficacité etLire la suite…

Apprendre le piano en ligne : quels sont les avantages de cette méthode d’apprentissage ?

Apprendre le piano n’est pas sorcier, il est assez simple et facile de s’entraîner, d’apprendre et de maîtriser cet instrument musical. Pour cela, vous pourriez vous inscrire dans une école de musique, sinon si vousLire la suite…

Comment se remettre d’un divorce : vous ne savez pas comment on se remet d’un divorce ?

Vous venez de mettre fin à un mariage qui a duré quelques années et vous ne vous sentez pas capable d’aller de l’avant ? Vous avez peur de ne pas pouvoir vous remettre de ceLire la suite…

Mariage oriental : est-ce qu’une telle organisation coûte chère ?

Le jour du mariage est le rêve le plus attendu de chaque fille spécialement et d’un homme amoureux généralement, c’est pourquoi chaque couple aimerait organisé son mariage selon ce qu’il veut voir se passer enLire la suite…

Référencement SEO : Pourquoi il faut passer par le SEO ?

Les agences web sont importantes car elles disposent des compétences professionnelles pour exercer dans la profession. Il y a de quoi prendre en considération le faut que le référencement est d’une qualité inédite. Il yLire la suite…

Meilleur VPN : où peut-on le télécharger ?

Aujourd’hui, nous allons parler sur un sujet qui devrait grandement vous intéresser. Il s’agit de l’utilisation d’un réseau VPN dans le but de vous protéger lorsque vous naviguer sur internet. Il est important d’adopter celaLire la suite…

Cave à vin : pourquoi une cave à vin ?

Une cave à vin est une pièce réservée à la conservation des vins et des alcools , généralement située au sous-sol , mais peut être aussi encastrable dans les cuisines d’aujourd’hui . Cet espace doitLire la suite…

Comment replier une poussette double ?

Pour vous promener avec vos jumeaux ou des enfants d’âge rapproché, la poussette double sera idéale et même indispensable ! Comme vous le lirez sur https://www.poussette-double.net, elle sera aussi utile aux assistantes maternelles. Vous verrez qu’ilLire la suite…

Extracteur de jus : comment choisir convenablement ?

Vous en avez assez d’avoir à presser des fruits manuellement pour en extraire le jus ? Et vous êtes à la recherche d’un moyen plus facile de préparer des jus naturels ? Pensez donc àLire la suite…

Payer moins d’impôts : Comment s’y prendre ?

N’aimeriez-vous pas alléger votre charge fiscale ? Evidemment tout le monde voudrait pas cette chance. Heureusement, il y a plusieurs choses que vous pouvez faire pour réduire vos impôts, ou augmenter le montant de votreLire la suite…

Voyage : est-ce le bol d’air dont j’ai besoin ?

Vivre une aventure dans un pays lointain, être livré a soi-même dans une jungle tropicale ou même marcher sur des pavés qui ont étés construits des siècles auparavant… Tout cela est possible grâce aux voyages,Lire la suite…

Épilateur lumière pulsée : Comment disposer de l’épilateur ?

L’épilation est un moment clé pour tous ceux qui ne veulent plus de poils. En effet il est important d’avoir une véritable option en matière d’épilation qui est aujourd’hui importante. C’est pourquoi il est utileLire la suite…

Comment protéger sa famille avec de l’investissement locatif ?

Vous êtes en pleine réflexion pour mieux savoir quels sont les bénéfices que vous allez générer grâce à l’investissement locatif ? C’est normal. C’est toujours un peu compliqué d’investir dans l’immobilier. Pourtant, il y aLire la suite…

Collier mariage : comment bien choisir le collier de mariage ?

Vous souhaitez compléter votre tenue de mariée avec un accessoire qui fera la touche finale de votre robe ? Un accessoire qui est à la fois chic et classe et qui tournera les regards deLire la suite…

Traces, images, paroles, messages… Il faut tout conserver !

Les captures d’écran sont des éléments indispensables pour toute personne qui réalise une activité quelconque sur Internet. Pour ce faire, il faudra choisir l’une des deux méthodes présentées par http://lydie-creation.fr sur un ordinateur Apple (Mac).Lire la suite…

Nouvelle mode ou pas : les adultes se mettent au coloriage !

Les adultes redeviennent des enfants. Ce aurait pu être le titre de cet article, mais cela ne l’est pas. C’est un constat : les adultes reprennent le coloriage. Pourquoi ? Dans quel but ? C’estLire la suite…

Blog généraliste Flomarian.fr : qui sont les lecteurs d’un blog généraliste ?

Parmi les avantages du net, la présence de sites personnels connus sous le nom blog. Les blogs se divisent en deux types, les blogs spécialisés et les blogs généralistes sujets de notre article. Nous allonsLire la suite…

Blog généraliste APM Online : comment lancer un blog généraliste ?

Vous comptez lancer un blog généraliste mais vous ne savais pas par où commencer ne vous inquiétez pas ce n’est pas très compliqué c’est même très simple il faut juste bien se renseigner avant deLire la suite…

Blog généraliste Banana Land : cherchez-vous un moyen efficace ?

Le blog web de manière générale est un journal de bord qui diffuses des contributions et des analyses concernant certains domaines, il peut être spécialiste comme il peut être généraliste. Vous pourrez avoir recours àLire la suite…

Mini four : comment l’entretenir ?

Avoir un mini four, que ça soit pour une raison d’économie d’énergie ou bien par ce qu’on manque d’espace dans sa cuisine pour y placer une cuisinière ou bien un four encastrable, les raisons sontLire la suite…

Musique : comment peut-on suivre l’actualité musicale ?

La musique fait partie de notre vie quotidienne, cette forme d’art représente l’expréssion humaine des sentiments cachés, l’homme exprime ces sentiments avec des sons et des rythmes qui peuvent se présenter sous forme d’œuvre musicale.Lire la suite…

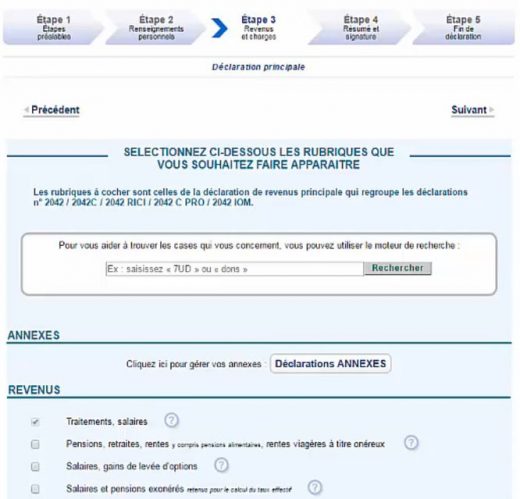

Loi Pinel Rennes : A partir de quand faut-il déclarer vos revenus fonciers ?

Afin d’augmente l’offre de logement face à la demande croissante et incontrôlable l’état a mit en place une loi qui est la loi pinel et qui aide les investisseurs dans le secteur de l’immobilier .Lire la suite…

EDF NICE : Choisir EDF Nice serait-il meilleur pour payer moins chère sa conso ?

Contrôler sa consommation énergétique n’est pas facile et c’est loin de l’être quand l’on dispose pas des moyens. Ces derniers sont proposés par le fournisseur EDF Nice. Avec un contrat adapté à vos besoins, vousLire la suite…

Connaître l’essentiel de l’actualité musicale : Quel site doit on choisir pour mieux y parvenir ?

Les médias de nos jours sont passés au mode numérique . Aujourd’hui , il est possible d’écouter la radio ou regarder les chaines télés en se connectant à l’internet . Les arts en général n’échappentLire la suite…

EDF Angers : que savez-vous à propos de ses offres ?

EDF ou énergie de France est une société Française qui assure le côté énergétique du pays. Parmi ses fonctions, la production, la commercialisation y compris la fourniture et le transport des éléments énergétiques du quotidienLire la suite…

EDF AIX EN PROVENCE : quelles sont les formules proposées par le fournisseur d’énergie EDF ?

Vous comptez déménager bientôt ? Vous ne savez toujours pas quel fournisseur d’énergie prendre pour votre nouvelle maison ? Vous avez envie de trouver un fournisseur offrant des formules qui vous conviennent ? Vous avezLire la suite…

Quels sont les atouts d’EDF Villeurbanne?

Lorsque vous déménagez, il faut penser à prévenir EDF Villeurbanne afin qu’il vous accompagne dans votre nouveau logement. Mais vous pourrez également les contacter si vous n’êtes plus satisfait de votre fournisseur d’énergie actuel etLire la suite…

EDF LYON : pourquoi choisir EDF ?

Devenir client chez EDF n’a jamais été aussi simple. Ce fournisseur connaissant beaucoup d’adhérents ne cesse de satisfaire ces derniers et d’attirer les consommateurs. Si vous avez choisi edf lyon ? vous avez pris laLire la suite…

Poêle en inox : Comment l’entretenir ?

Il existe des centaines voire des milliers de modèles et de marques de poêles, toutes ou presque toutes dotées de nouvelles technologies, qui permettent d’après eux, une cuisson performante et innovante. Mais que faire quandLire la suite…

Marche pied poussette : comment bien choisir ?

Les marches pieds poussette sont devenus des produits indispensables pour de nombreux parents à travers le monde. En effet, il s’agit d’un accessoire que vous pouvez fixer à votre poussette et qui vous permettra d’yLire la suite…

Compresseur 100l : comment choisir?

Le compresseur 100 l est un matériel qu’on utilise souvent pour le gonflage des pneus, pour faire de la peinture,… La gamme de compresseur 100 l est très large et variée, si vous n’avez jamaisLire la suite…

Et si vous essayez votre matelas pour clic-clac avant de l’acheter ?

Lorsque vous achetez un clic-clac, il est toujours fourni avec un matelas en mousse. Tout simplement parce que c’est le modèle le moins cher. Il sera parfait quand vous vous servirez de votre clic-clac enLire la suite…

EDF MONTPELLIER : Numéro 1 en Hexagone ?

EDF est une agence qui produit et fournit de l’énergie dans les quatre coins de l’hexagone. Quasiment, tous les citoyens français jugent meilleure la qualité de l’énergie d’EDF. Si vous aussi, vous voulez tenter laLire la suite…

Quelles solutions EDF Reims peut-elle vous proposer?

Quand vous emménagez dans une nouvelle maison ou que vous trouvez que vous payez trop cher en électricité, il ne faut pas hésiter à vous rapprocher d’edf reims. EDF Reims: lequel de ses contrats répondraLire la suite…

Déménageur : combien coûte un déménagement hors de France ?

Vos coûts de déménagement seront en grande partie déterminés par leur poids et la quantité d’espace qu’ils occupent. Diminuer vos possessions peut réduire vos coûts de déménagement et même vous aider à mettre de l’argentLire la suite…

Comment bien choisir son bien immobilier ?

Si vous envisagez de déménager, le choix de votre bien immobilier est une étape primordiale. Ainsi, vous devez non seulement vous décider sur le type de produits mais aussi sur la zone géographique envisagée. QuelsLire la suite…

Paris sportifs : Gagner tout le temps c’est bien ?

Jouer dépend du bon vouloir du parieur. Jouer veut aussi dire qu’il y a une véritable correspondance autour de la volonté du parieur à vouloir se faire quelques gains qui peuvent asseoir une légitimité déterminanteLire la suite…

Paris sportifs : est-ce votre première fois ?

Pour ce qui est des paris sportifs des jeux sur mesure et attirants pour les amateurs de sport généralement, de ce fait on trouve les paris sportifs dédiés au football ,au hockey ; au tennisLire la suite…

Déménagement Paris : est-ce possible de s’installer à Paris avec un budget limité ?

Cela peut sembler cher de déménager à Paris au premier abord, mais il n’est pas impossible de bien vivre à Paris avec un budget limité, avec de nombreux marchés alimentaires, des événements gratuits et desLire la suite…

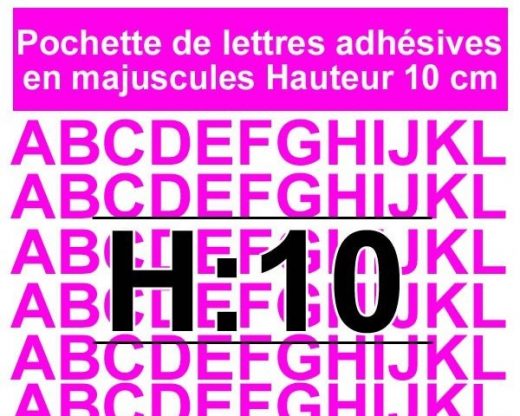

Lettre autocollante : comment l’utiliser ?

Sommaire: Vous êtes un adeptes de l’écriture, vous aimez les autocollants que vous pouvez mette là ou vous voulez, sur votre journal intime, sur votre mur, sur votre bureau, pour donner un charme et plusLire la suite…

EDF Marseille : comment souscrire chez lui?

Quand protéger notre univers est une priorité pour nous, nous œuvrons avec tout ce qu’il y a en notre pouvoir pour y parvenir. Souscrire chez EDF Marseille va nous permettre de consommer tout autant d’énergieLire la suite…

EDF Nimes : Pourquoi choisir ce fournisseur ?

Vous entendez souvent parler d’EDF mais vous n’arrivez pas à comprendre c’est quoi au juste ? Tout le monde vous parle de ses offres et de ses avantages et vous vous ne savez pas deLire la suite…

Servante d’Atelier : Quelle utilité ?

La servante d’atelier, vous permet dans un premier temps, le rangement de tout vos outils dans un compartiment spécifique. Elle vous permet : La disponibilité de vos outils, en cas de besoin Elle vous évite,Lire la suite…

Lunette astronomique : En quoi diffère-t-elle du télescope ?

La lentille est de nos jours utilisée par un important nombre de personnes , discrète et simple , elle a même réussie à remplacer chez certaines personnes leurs lunettes traditionnelles . Ce petit objet ,Lire la suite…

Acouphène : quels sont les sons que l’on entend dans un acouphène ?

Si vous venez seulement d’entendre parler de ce symptôme et que vous ne savez pas à quoi vous attendre. Ou au contraire, si vous en souffrez, que vous ne cessez d’entendre des bruits de parasitesLire la suite…

Paris sportifs : comment bien débuter ?

Vous avez du mal à boucler vos factures ce mois ci, et vos crédits et dettes n’arrêtent pas de s’accumuler ? Une seule solution pour vous sortir de là, tentez le paris sportif ! LeLire la suite…

Lave vaisselle profesionnel : comment faire le bon choix ?

Vous dirigez un restaurant ? Ou bien vous êtes parent d’une famille nombreuse ? Dans les deux cas, vous en conviendrez, que faire la vaisselle est à la fois une tâche pénible et fatigante àLire la suite…

Loi Pinel Marseille : un moyen de se faire rapidement de l’argent ?

Vous cherchez un bon investissement sur le long et court terme afin de vous faire de l’argent ? Vous souhaitez vous investir dans l’immobilier mais vous ne souhaitez pas déménager de votre maison actuelle pourLire la suite…

Paris sportifs : comment procéder pour placer son premier pari ?

Le paris sportif est en train de devenir de plus en plus populaire ces dernières années car il a pu offrir aux parieurs la possibilité de jouer en ligne et parier sur les résultats deLire la suite…

Paris sportifs : aimeriez-vous vivre de votre passion ?

Pourquoi vivons-nous sur cette terre ? Pourquoi sommes-nous là au juste si ce n’est que pour vivre pleinement sa passion ? En effet vivre l’expérience de ce qui vous fait sursauter et combler de joieLire la suite…

EDF AMIENS : relevé d’identité bancaire (RIB)

Vous avez tendance à oublier votre facture ? ou vous n’avez pas le temps de vous en acquitter. Opter pour un prélèvement direct, à partir de votre compte, sans vous soucier du règlement de vosLire la suite…

EDF LILLE : Quelles sont les propositions d’EDF Lille ?

Le fournisseur que vous aurez choisi relève d’une grande importance, et ce, pour plusieurs raisons. C’est pourquoi nous vous proposons d’opter pour un contrat EDF Lille. Votre contrat sera efficacement géré. Pour le choix d’unLire la suite…

EDF ANNECY : que préférez-vous ?

Si vous faites une recherche concernant les fournisseurs sur internet, vous en trouverez beaucoup, une large liste de fournisseurs d’énergie vous sera mise en place, mais sachez que ce ne sont pas tous les fournisseursLire la suite…

Électricité Amiens : quels sont les aides pour les foyers à faibles revenus ?

Que vous utilisiez ou non l’électricité pour chauffer votre maison, si vous êtes à faible revenu, vous avez droit à un tarif d’électricité réduit. Le tarif réduit de l’électricité est appelé Tarif de Première NécessitéLire la suite…

Paris sportifs : qui a dit qu’il n’était pas possible de gagner de l’argent en s’amusant ?

Entre dépenses au foyer , famille , dépenses personnelles , il reste peu de place au risque , miser n’importe comment en serait un , cependant nos experts sont là pour vous aider à minimiserLire la suite…

Déménageur : Les déménagements ne seront plus aussi éprouvants pour vous !

Vous avez acheté une nouvelle maison et vous cherchez un moyen de transporter facilement toutes vos affaires jusqu’à celle-ci ? Vous allez bientôt déménager et vous n’avez pas le temps ni l’énergie de tout transporterLire la suite…

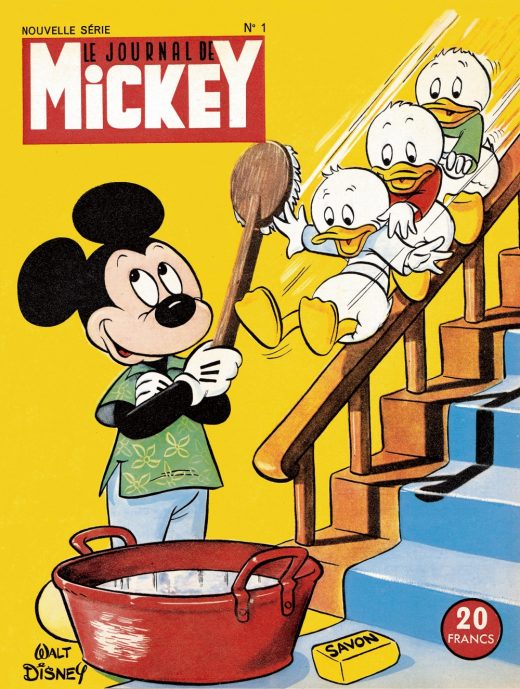

Journal de Mickey : tout savoir sur ce journal pour enfant ?

Votre enfant aime la lecture ? Dans ce cas, en plus de lui proposer d’emprunter des livres à la bibliothèque, pourquoi ne pas l’abonner à un magazine, par exemple le journal de mickey ? NousLire la suite…

Paris sportif : quel paris prendre en compte ?

Si nous nous référons aux informations fournies par le bon site votreparis-sportif.info, vous pouvez dès maintenant commencer par faire les choses correctement et cela en vous intéressant aux paris sportifs. Pour ceux qui ne leLire la suite…

Casino en ligne : comment trouver le meilleur site casino en ligne sur un guide ?

Jouer au casino en ligne vous parait un peu virtuel, mais une fois que vous avez décidé de chercher un bon site sur le guide Casino Légal France, vous vous rendrez compte assez vite qu’ilLire la suite…

Chaussettes chauffantes : Elles sont faites pour les femmes ou pour les hommes ?

Chaque jour, de nouvelles inventions sont commercialisées, On y voit de toutes les couleurs sur le marché, pour tous les goûts et pour tous vos besoins. Les prix varient d’un produit à un autre, lesLire la suite…

Meilleure Imprimante Laser : plus performante que les autres types ?

Dans un bureau, une administration ou même chez soit il est toujours utile et pratique d’avoir une imprimante à sa disposition pour imprimer ou faire des copies de documents utiles pour le travail. Une imprimanteLire la suite…

Comment donner une seconde vie à un sauteur pour bébé?

Quand vous décidez d’acheter un sauteur pour bébé, c’est pour que votre enfant puisse découvrir la position verticale et ainsi pour faciliter l’apprentissage de la marche. Comme vous le lirez sur https://www.sauteurbebe.com, cet équipement convientLire la suite…

Ventilateur sur pied: à la recherch d’un bon ventilateur ?

Cher lecteur, si vous êtes à la recherche d’un ventilateur et que vous ne savez pas pour lequel opter et que vous souhaitez surtout régler ce problème avant l’arrivée de l’été avec ses canicules etLire la suite…

Robot aspirateur laveur : comment bien choisir ?

Les tâches ménagères demandent un effort considérable, ainsi que d’y consacrer beaucoup de temps. Et les réaliser manuellement peut rapidement engendrer une grande fatigue, d’autant plus que le résultat obtenu n’est pas toujours satisfaisant. DansLire la suite…

Appareil photo polaroid: pourquoi pas s’offrire un appareil photo polaroid?

Bien que ce dernier année smartphone avec leurs performances remarquables ont remplacé les appareils photos, ceci font leur un retour en force avec les appareils de photos Polaroïd qui vous permettent de profiter de votreLire la suite…

Lit escamotable : Pourquoi le choisir ?

Vous vivez dans un petit appartement et vous n’avez pas beaucoup d’espace pour circuler ? vous avez un lit qui est encombrant surtout avec les autres meubles que vous possédez ? Vous voulez trouver uneLire la suite…

Scie plongeante: quel est le meilleur comparatif?

Pour les bricoleurs, il y a un outil très intéressant qui est la scie circulaire ou la scie plongeante. Cette machine est utilisé pour couper de gros morceaux de bois tel que les bastaings etLire la suite…

Matelas 140×190 : pourquoi et comment trouver un matelas de qualité ?

Vous êtes tout le temps fatigué avec votre travail et des journées très fatigantes ? Le choix d’un matelas de qualité mettra un terme à cette fatigue de tous les jours. Dormir sur un matelasLire la suite…